Premium precast concrete solutions

At Ozcast, we specialise in delivering top-tier precast concrete elements for various sectors, including Australian infrastructure, rail, and commercial projects. Our commitment to quality ensures that we provide the highest standard of precast concrete products, tailored to meet the rigorous demands of our clients.

Products we manufacture

We offer a large variety of precast elements in various finishes, from plain off form to custom architectural with various colours.

Precast Parapets / Traffic Barriers

An essential safety solution for highways and bridges, providing protection and delineation for road users.

Precast Tilt Up Panels

Efficient and versatile building components, ideal for rapid construction of walls and facades.

Precast Retaining Walls

Engineered to stabilise soil and create level surfaces, perfect to help provide structural support on infrastructure projects.

Precast Panels / Structures

Customisable precast elements made to order, for diverse architectural and infrastructural applications.

Precast Noise Walls

Designed to mitigate sound pollution, ensuring quieter environments near roads and industrial areas.

Precast Structural Panels

Durable and high-strength solutions for critical load-bearing applications in road and rail infrastructure projects.

Precast Arches

Functional and aesthetic precast components, ideal for entrances and bridge construction.

Our process

Ozcast can manufacture and supply a variety of precast elements for your project. With a focus on exceeding customer expectations from both a service and quality perspective, it’s been important that we develop a methodology that allows us to deliver consistently.

How we work

When you engage us for your next project, you can be guaranteed that we will follow a robust process to ensure the best result.

Design Checks

Designing our moulds with the highest accuracy means we can produce end products of the highest quality. The result? A reduced likelihood of any misalignments onsite. Once your designs are received, we prepare, inspect, clean and prep the moulds so they are ready for production.

Pre-production checks

We print 3D mockups of the finished product, and test drawings at 1:1 scale of each steel bar design required for production. These drawings are then forwarded to the steel supplier to allow a quality check that the steel is bent to the correct shape.

Moulding tests

We ensure all elements of the parapet, including cage and steel, are aligned within the mould, and cast a quality sample to test this.

Post-production testing

We observe the production of each cast closely, checking for any anomalies that could cause delays.

Delivery of finished product

Once products are complete, we deliver to site using experienced transport professionals, to ensure a safe and effective delivery without damage to the load.

What sets Ozcast apart?

We go the extra mile to transform architectural visions into concrete realities. High level service is the defining principle of our constructions.

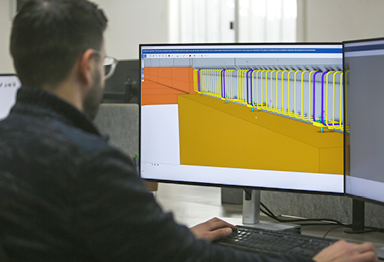

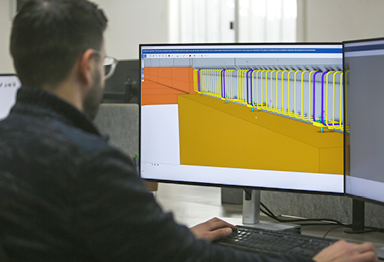

3D Rendering

A key benefit to our clients is our use of rendering as standard. We take a 2D design and render it into a 3D model of the individual componentry, as part of the overall project render. The ability to visualise steel placement within the parapet prior to production allows clash detection, meaning that necessary changes can be undertaken as part of the design phase. As a result, we avoid delays during installation, and on some projects, we’ve been able to cut installation times in half, leading to substantial savings in both time and projected budgets.

3D Modelling

Quality Moulds

Our products’ ultimate performance can be directly attributed to the high quality of our moulds. For each project, we tailor solutions by designing robust steel moulds, which are made using materials from proven national and international steel suppliers.